About Us

Huizhou Hensein Bio-Environmental Technology Co.,Ltd. is one of famous and old companies in Huizhou of Guangdong. Hensein Bio Bags Co.,Limited is our Hongkong company.

Hensein specialized in R&D and productions of all kinds of compostable bags. We developed new products and made finished products for tens of compostable materials-making companies. All our products meet the EU standards. And in Belgium OWS detection mechanism, our products comprehensively passed through DIN CERTCO composting degradation test and obtained the Home compostable and Industrially compostable certificates, meet EU-EN13432, USA-ASTMD-6400, FDA food grade etc standards.

Our products are exported to Australia, Britain, New Zealand, America ,Brazil, Japan, South Korea , Denmark, Norway, France and other countries.Our company is the leading enterprise in quality and technology in this field.

Production Workshop

Production Workshop

Main Market

Our products are exported to Australia, Britain, New Zealand, America ,Brazil, Japan, South Korea , Denmark, Norway, France and other countries.

Description of Each Control Crital Points

| Production Step | Control Point | Target and Range | Control Procedure | Frequancy | Responsible | Correction Acction | Documents | |

| 1 | Blowing film | Surface | 99~100 | Color,cleanness | at any moment | film color consistent with customer sample or information requirements, no color difference, no dirty points and other defect. | adjustment and enviaronment control | IPQC |

| 2 | Blowing film | specification | 99~100 | Thickness and size | One hour | Thickness ≤±0.01mm; Size≤±1mm | Film machine adjustment | IPQC |

| 3 | Blowing film | Raw material | 100 | Right material | Before producing | Use right raw material,meet request of order. | Change to right material in time | IPQC |

| 4 | Printing color | Surface | 99~100 | Color | One hour | Color, picture, text, content should be consistent with the confirmation template, can not have double shadow, dirty, walking, miscellaneous points, missing strokes, fat oil, font confusion and other defect. | Printing adjustment | IPQC |

| 5 | Printing color | specification | 99~100 | location | One hour | The font position ≤±1.5 mm, the printing position is the same as the template. | Printing adjustment | IPQC |

| 6 | Printing color | Firm testing | 99~100 | firm | One hour | Using transparent adhesive tape paste 3-5 seconds ,45° angle quickly tear up, no color loss. | Printing adjustment | IPQC |

| 7 | Cutting bag | Surface | 99~100 | Hot sealing,dirty | at any moment | Hot sealing location and effect is right and good,no dirty. | Cutting machine and temperature adjustment | IPQC |

| 8 | Cutting bag | specification | 99~100 | size | One hour | Size mirror≤±1mm | Cutting machine adjustment | IPQC |

| 9 | Packaging | Surface | 99~100 | Accuracy,dirty | at any moment | Product packaging and production instructions sheet consistent with,the bag can not be reversed, wrong, more or less loading phenomenon, bag must not have hair, debris, dirty, leakage accessories and other bad, packaging intact without damage, bag mouth to seal flat. | Inspection in time | IPQC |

| 10 | Packaging | specification | 99~100 | size | One hour | Packaging bag size error≤±1.5mm;Carton size error≤±3-5mm | Inspection in time | IPQC |

| 11 | Packaging | testing | 99~100 | firm | Begin packing | Drop test (refer to whole box drop test procedure) | Inspection in time | IPQC |

Product Degradation Process

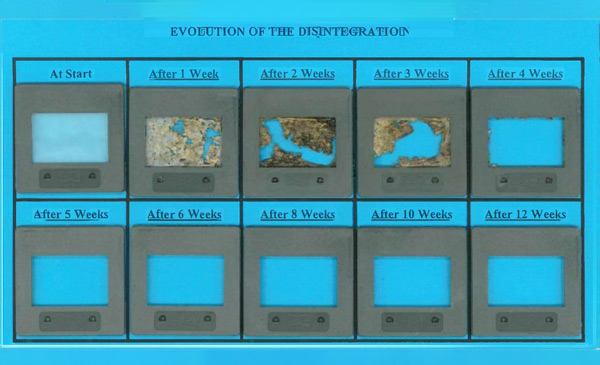

Process of biodegradation as below (tested by OWS in accordance with standard test conditions)

Figure 1. Visual presentation ofthe test item (lefi: film sample-right: pellets)

Figure 2. Presentation of the content of at test bin with 10%(1% 10×10 cm pieces& 9% milled pellets) after I week of composting

Figwe 3.Vsual comparison beiween (55 μm) at starand afier 2 weeks of composting

Figure 4. Presentation of the contentofa test bin with 10% (1% 10×10cm pieces & 9% milled pellets) after 4 weeks of composting.

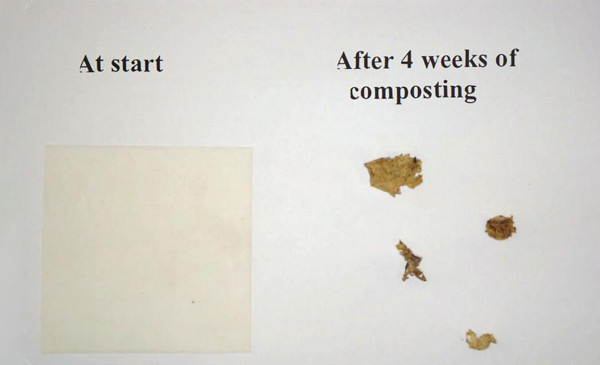

Figuve 5. Visual comparison berween (55 μm) at start and afier 4weeks of composting

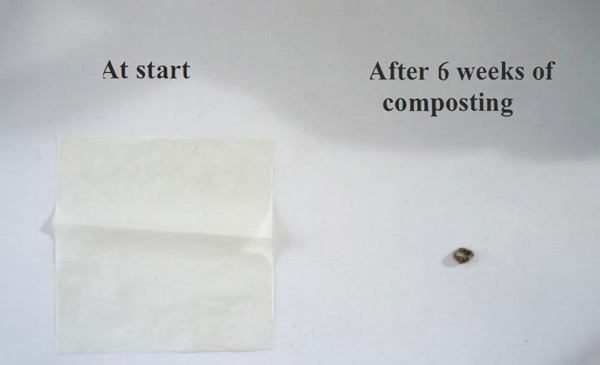

Figuvre 6. Visual comparison berween (55 μm) at start and after 6 weeks of composting.

Figure 7.Visual comparison of the< 10 mm fraction ofcontrol (left) and ours compost (right) <10 mm fraction of <10 mm fraction of ours compost control compost at the end ofthe composting process.

Why Choose Us

Rich Experience

Over 16 years of dedication to biodegradable&compostable products.

Cheap Price

From resin to finished product,all produced by ourself,one-stop solutions save cost.

Well Quality

We guarantee our products would be composted into water and carbon dioxides within 3 months in industrial facilities. and also guarantee them maintain their physical properties for 12-15 months,no biodegradable in advance.

Complete Certifications

Our products comprehensively passed through Home compostable and Industrially compostable certificates, meet EU-EN13432, USA-ASTMD-6400, FDA food grade standards. Make sure you can use and sell safely!

OEM Customized

Working out the finished products begin from your idea!Support fully from our R&D and whole team!

Good Faith

Inspect goods strictly and fast delivery.We value your time!Value your investment!Keeping more better service after sell!