Seeking Reliable Private Label Manufacturing for Biodegradable T-shirt Bags?

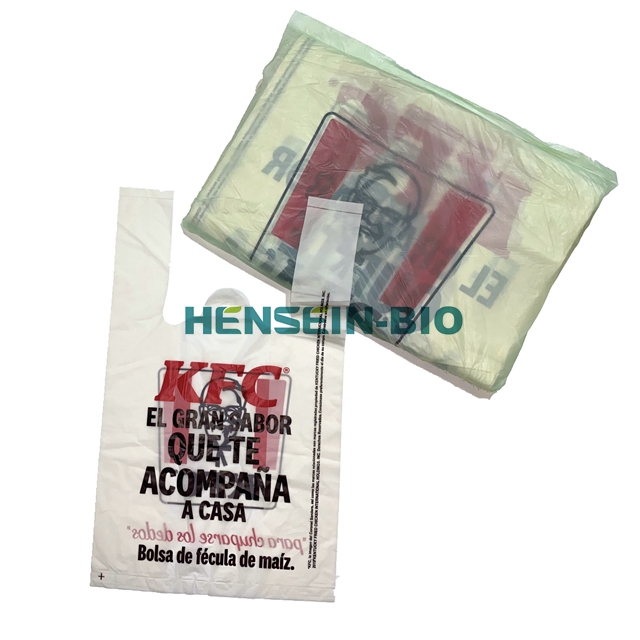

Wholesalers and distributors often face challenges finding manufacturing partners that combine large-scale production capacity with consistent quality and certification compliance. Issues like delayed shipments, inconsistent product quality, and inadequate documentation can disrupt supply chains and damage business reputation. As a global wholesaler and manufacturing partner, Hensein provides comprehensive private label biodegradable T-shirt bag solutions. Our integrated manufacturing facility ensures quality control from raw materials to finished products. We offer complete OEM services including custom formulation, size customization, and private label printing, making us the preferred choice for international wholesalers seeking reliable, certified compostable bag supplies.

Hensein is a global wholesaler and manufacturing specialist for private label biodegradable T-shirt bags. We cater to growing global demand with scalable production, trend-responsive designs, and comprehensive OEM services. Our Chinese manufacturing base ensures competitive pricing and reliable supply for international partners.

Global Manufacturing Capabilities and Customization

Our manufacturing capabilities support global demand with scalable production and consistent quality assurance. We operate advanced production lines capable of manufacturing various biodegradable T-shirt bag styles and sizes to meet diverse market requirements. Our private label services include complete branding options, from simple logo printing to fully customized bag designs. We maintain comprehensive certification documentation for international shipments and market compliance. With extensive experience exporting to global markets, we understand the specific requirements of different regions and help wholesalers develop products that meet local regulations and consumer preferences while maintaining cost efficiency.

Why Wholesalers Prefer Chinese Biodegradable Shopping Bag Factories

Wholesalers increasingly prefer Chinese biodegradable shopping bag factories for their combination of cost efficiency, manufacturing scale, and technical capability. Chinese manufacturers offer integrated production from raw material to finished product, eliminating multiple supply chain markups. The manufacturing infrastructure supports large volume production with consistent quality control, ensuring reliable supply for wholesale distribution. Chinese factories have rapidly advanced their technical expertise in compostable materials, now producing bags that meet international certification standards. The competitive pricing, coupled with improving quality and certification compliance, makes Chinese manufacturers attractive partners for wholesalers serving global markets with price-sensitive yet quality-conscious customers.

Global Demand for Biodegradable T-shirt Bags

Global demand for biodegradable T-shirt bags is experiencing rapid growth driven by environmental legislation, consumer awareness, and corporate sustainability initiatives. Markets in Europe and North America lead adoption, with Asia-Pacific regions accelerating implementation of plastic restrictions. The demand spans multiple sectors including retail, hospitality, and events, creating diverse market opportunities. This growth is supported by improving product quality and performance, eliminating earlier barriers to adoption. Market analysts project continued expansion as more regions implement plastic bans and consumers increasingly prioritize environmentally responsible packaging. The universal applicability of T-shirt bags across industries ensures sustained demand growth for compliant alternatives.

Private Label Biodegradable T-shirt Bag Manufacturing

Private label biodegradable T-shirt bag manufacturing enables brands to market eco-friendly packaging under their own branding while leveraging professional manufacturing expertise. This approach allows companies to maintain brand consistency across their packaging while ensuring product quality and certification compliance. Private label manufacturing typically includes custom sizing, material specifications, and printing options tailored to brand requirements. Manufacturers handle the complex aspects of material formulation, production, and certification, while brands focus on marketing and distribution. This partnership model provides businesses with competitive advantages in sustainability-focused markets while minimizing investment in production infrastructure and technical expertise.

Trends in Biodegradable Carrier Bag Designs

Biodegradable carrier bag designs are evolving to enhance functionality, aesthetics, and environmental performance. Current trends include minimalist designs that reduce material usage while maintaining strength, and vibrant printing using eco-friendly inks that maintain compostability. Ergonomic improvements focus on handle comfort and load distribution, enhancing user experience. Design trends also incorporate educational elements about proper disposal and environmental benefits, turning bags into communication tools. Advanced material blends enable thinner gauges without sacrificing performance, reducing material consumption. These design innovations respond to consumer preferences for attractive, functional packaging that aligns with environmental values while meeting practical needs.

How Biodegradable Shopping Bags Support Zero-Waste Stores

Biodegradable shopping bags play a crucial role in zero-waste store operations by providing a compliant solution for customers who forget reusable containers. These stores emphasize package-free shopping but need backup options for exceptional circumstances. Biodegradable bags offer an environmentally responsible alternative that aligns with zero-waste principles when composted properly. They serve as educational tools, demonstrating practical compostable solutions to customers. The bags' certification provides assurance that they will break down completely, unlike conventional plastics that contradict zero-waste values. This approach maintains operational flexibility while staying true to environmental commitments, supporting the growth of sustainable retail models.

How Biodegradable Shopping Bags Decompose in Compost

Biodegradable shopping bags decompose in compost through biological processes where microorganisms break down the material into natural compounds. In industrial composting facilities, controlled temperature, moisture, and aeration optimize conditions for microbial activity. The bags first fragment into smaller pieces, then microorganisms metabolize the polymers into carbon dioxide, water, and biomass. This process typically completes within 3-6 months in industrial settings, leaving no toxic residues. Home composting follows similar principles but at slower rates due to less controlled conditions. Certification standards verify complete biodegradation within specified timeframes, ensuring bags contribute to compost quality rather than contaminating the final product with microplastics or harmful substances.

About HENSEIN-BIO

HENSEIN-BIO is a professional 17+ years manufacturer in producing Home compostable & biogegradable bags including garbage bags , trash bags ,poop bags, dog bags, T-shirt bags, shopping bags, produce bags, handle bags and so on. We own the certificates of SGS, EN13432,ASTM D-6400, FDA food grade certificate, support color /size customization.

Welcome to consult for Catalog and Product. you can contact us at email [email protected]